Braiding and Winding

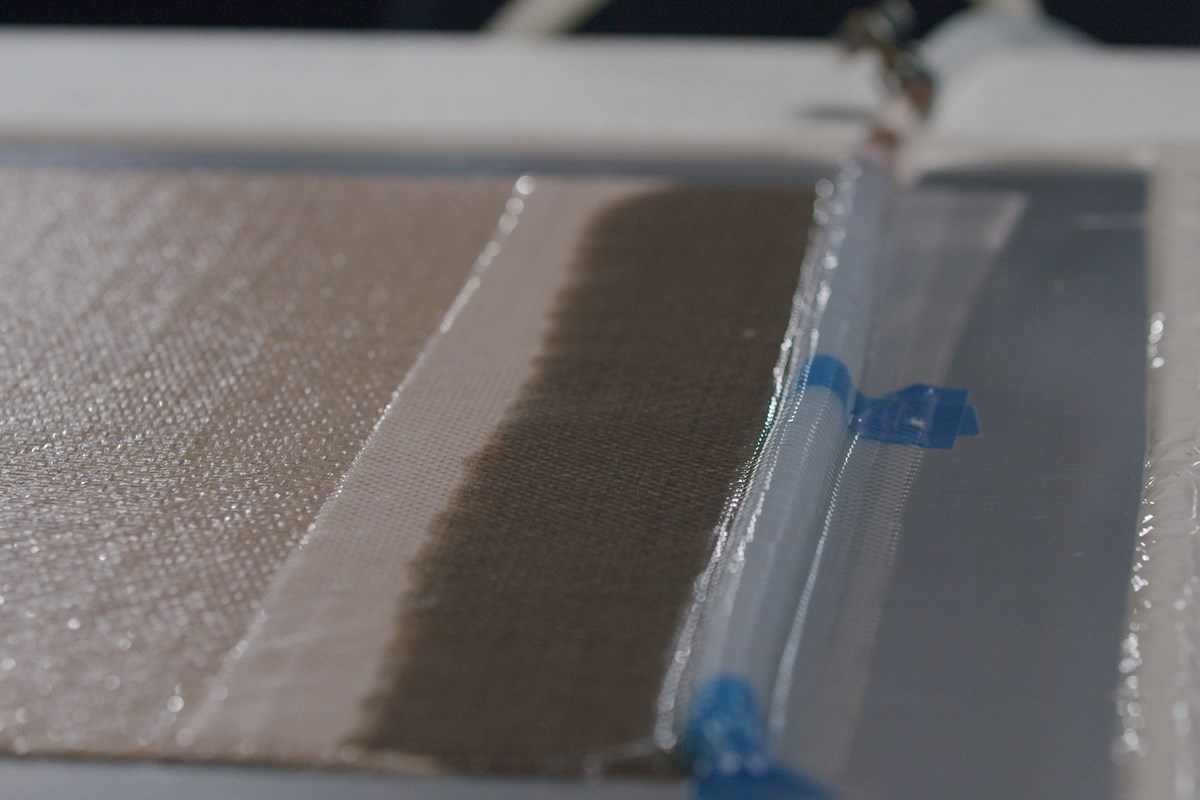

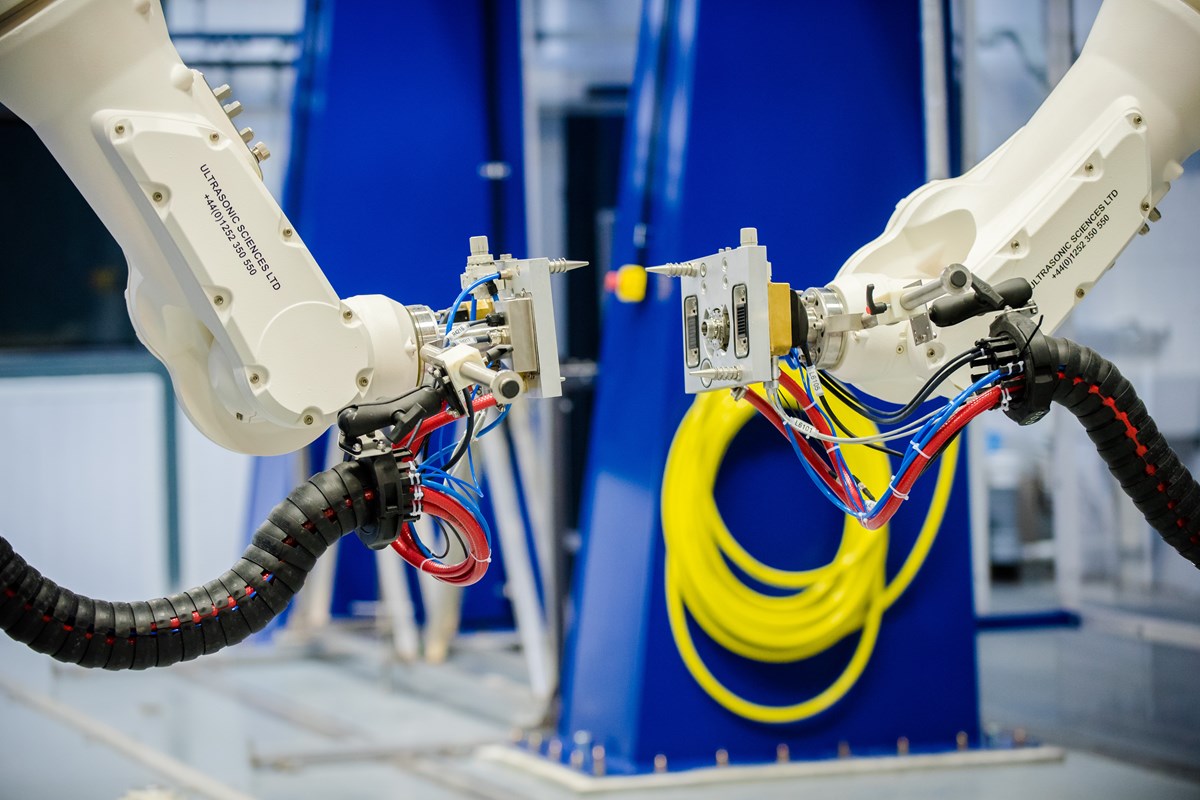

Our twin-ring braider can create components that are hollow and straight or complex cross sections with curved profiles. Our tape winder and filament winder machines can create anything from high-strength pipes to high pressure type 4 hydrogen tanks.