Develop inspection methods

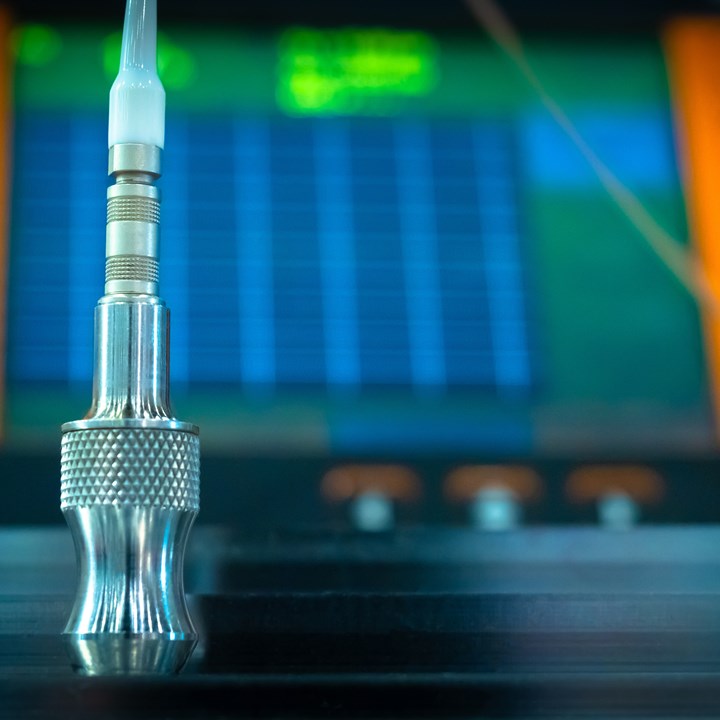

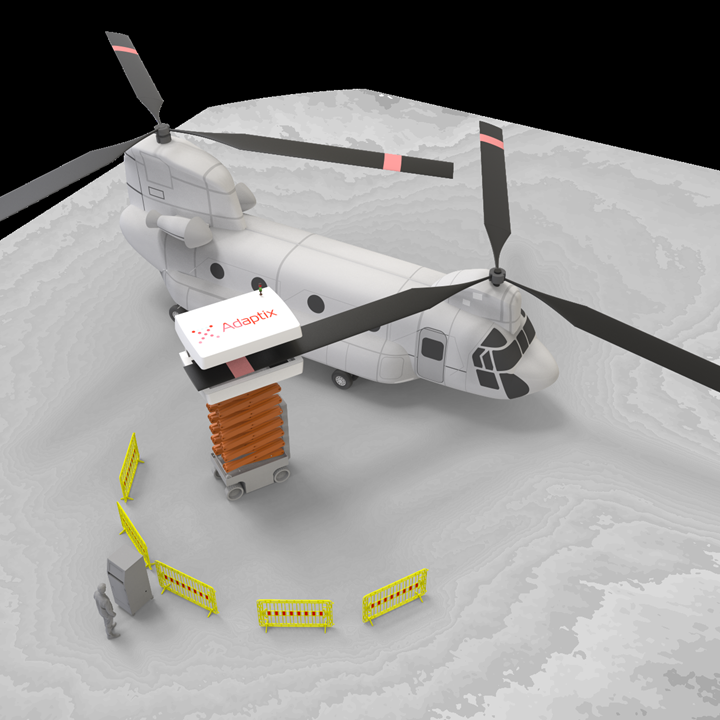

We offer access to expertise and technology to develop manual and automated inspection methods that are right for your products and processes. Our experts use the latest industry approaches to deliver balanced solutions across rate, cost and technical performance.

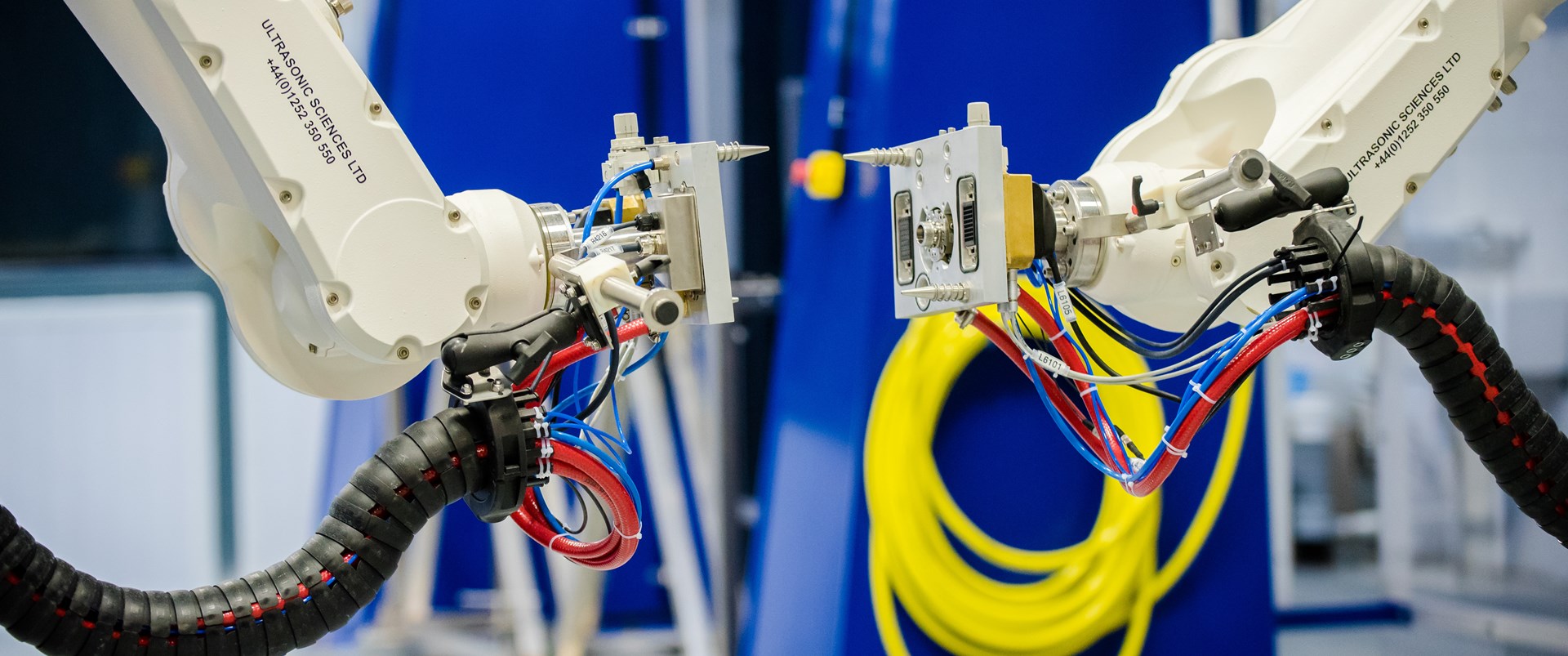

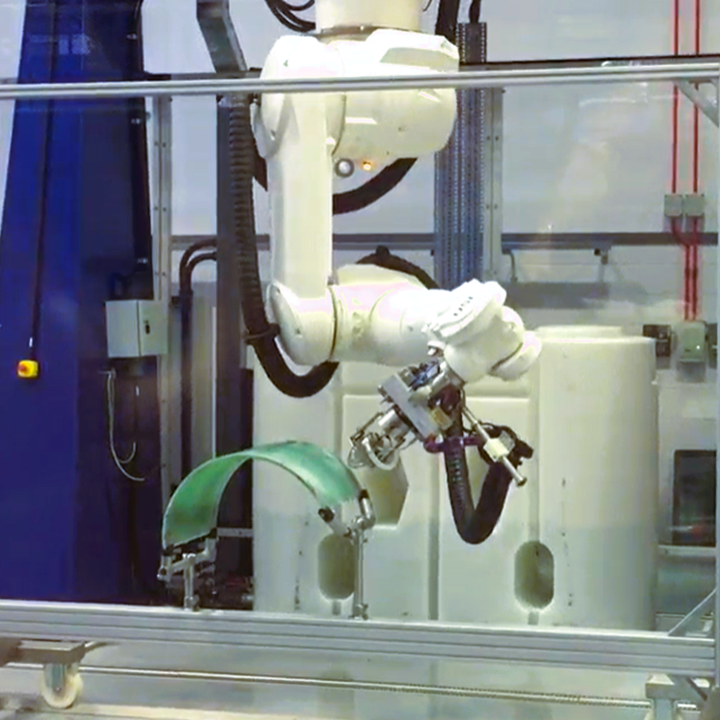

Utilising our state-of-the-art automated verification cell, we can take your inspection processes one step further, to support ever increasing rate and quality demands.

We can help to de-risk investment and supply chain development through process development and industrial scale demonstration on our equipment.