16 January 2024

In an exciting collaboration, Sonichem, an innovative clean tech company, embarked on a transformative project with the Innovation Centre for Applied Sustainable Technologies (iCAST). This partnership aimed to harness the potential of lignin in developing advanced sustainable materials that offer an alternative solution to fossil-derived materials.

Formerly known as Bio-Sep, Sonichem is at the forefront of revolutionising the production of green chemicals using ultrasonic technology. Their mission revolves around maximising the value of the world's green resources, and creating the chemicals we need to thrive in a way that is sustainable and benefits future generations. The Innovation Centre for Applied Sustainable Technologies (iCAST) is a unique collaboration set to deliver agile innovation in green, sustainable technologies. Bringing together experts across all the innovation stages ,it focuses on uniting industry and academia to translate discoveries into commercial application. The National Composites Centre is a proud member of iCAST.

Challenge

Lignin, a naturally occurring organic substance, is particularly prevalent in woody plants. It plays a pivotal role in the construction of cell walls in wood and bark, contributing to structural integrity and resistance to decay.

Despite its abundance on our planet, lignin often ends up as a by-product of the papermaking process, underutilised and either discarded in landfills, or incinerated due to its limited commercial applications.

Being a 100% bio-derived, renewable product, lignin presents a promising opportunity as are placement to fossil-derived materials in composite products as diverse as sports equipment and construction materials. There exists a wealth of academic literature on this subject, but little, if any, has made its way into commercial use.

The challenge tackled at the National Composites Centre revolved around identifying viable commercial prospects for using lignin in composite materials, capitalising on its renewable and entirely bio-based characteristics. This effort aimed to support a shift away from fossil-derived materials, ultimately reducing our environmental footprint, whilst also exploiting the added functionality of lignin including its fire- and UV-resistance.

Innovation

The NCC has a vision for sustainable materials and as such supports a broad portfolio of related research, from durability and recycling, through to exploration of biopolymers such as lignin, and natural fibres including flax and wool. Consequently, the partnership with iCAST aimed to push the envelope of what is possible in composites, using Sonichem’s products. The NCC’s technical contribution to the programme included engineering services in mechanical testing, manufacture, formulation, and thermal analysis.

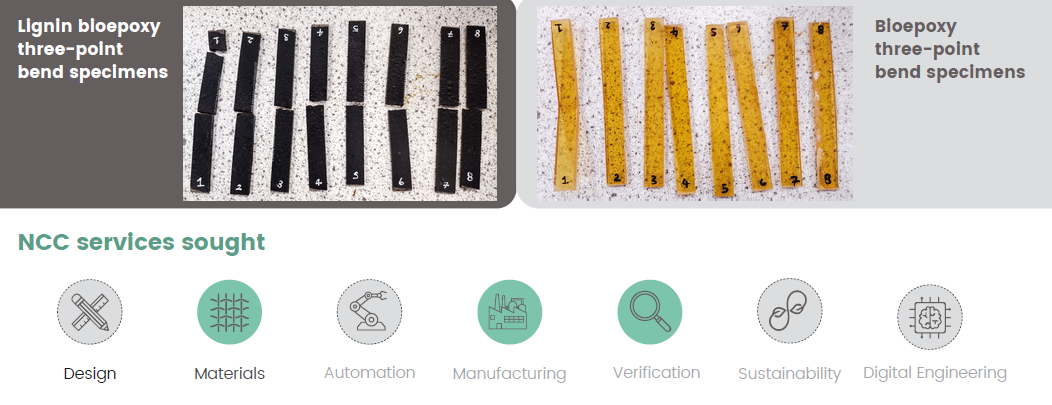

Utilising calorimetry and rheology, the team determined optimal processing parameters crucial for manufacturing. Then, leveraging the NCC’s expertise in resin formulation and compression moulding, the in-house team successfully produced composite components. Mechanical testing was then used to precisely measure the influence of lignin on the mechanical performance of the materials. Finally, the results of the wider project were drawn together to make recommendations for suitable commercialisation routes.

Results

This collaboration led to the successful manufacture of various components using biomaterials such as lignin, flax, and wool. The partnership between the National Composites Centre and iCAST provided valuable insights into the integration of Sonichem's lignin into composites.

Notably, the analysis unveiled the remarkable suitability of Sonichem's lignin for chemical treatment and manufacturing, due to its solubility and low viscosity. In contrast to other commercially available lignins, the Sonichem material has high solubility in a range of organic solvents. This characteristic means that their lignin is ideal for exploiting the range of chemical reactions that have been reported in the academic literature for enhancing the material properties, such as fire resistance. Improved solubility implies both that existing reactions may be easier and that new reactions will be accessible.

Furthermore, among all observed commercial lignins, only Sonichem’s lignin displayed the unique ability to melt and flow at sufficiently low temperature to facilitate fibre impregnation, meaning that Sonichem’s lignin is well-placed for development into composite moulding materials.

Impact

Previous lifecycle assessment (LCA) data from the NCC Bio-Bolster project gives an illustrative picture of the potential impact that biomaterials can have in composites. In Bio-Bolster, wind turbine manufacturing was modelled with a range of commercial bioresins as a demonstration of biomaterial use in high value composites. The LCA revealed that a representative bio resin had a 45% lower global warming potential than the equivalent, fossil-derived material. This figure highlights how increased use of bio-derived materials like lignin can pave the way for more sustainable composites in the future.

In this project, through the incorporation of lignin, the biogenic carbon content of a bioepoxy formulation was successfully boosted from 50 to 60%. Biogenic carbon is the carbon that is, or in this case, was stored in biological materials, such as plants or soil. The hope is that through subsequent research, larger fractions of lignin may be used, further boosting the biogenic carbon content. Moreover, by employing natural fibre reinforcements, including flax and wool, we demonstrated that it is possible to produce composite materials with a vastly reduced dependence on fossil fuels. This further enhances the development of sustainable composite materials.

Despite the formal closure of this project, some activities remain ongoing, which will continue to build the impact of this programme. A significant concern among composite designers regarding emerging biomaterials relates to their long-term environmental durability—an aspect rarely tested and not well modelled. Leveraging the intrinsic UV-resistance found in lignin, our objective is to conduct a comparative analysis of durability between materials with and without added lignin. This initiative aims to build consumer confidence in bio composites by substantiating the potential of lignin to enhance and ensure the enduring performance of these materials over time.

Dr Andy West CChem. CSci. FRSC, Chief Chemist, Sonichem Technologies Limited says:

"We believe Sonichem lignin has the ability to significantly defossilise the chemicals industry of the future, and this project, aided by skilled and knowledgeable staff and world-class equipment at the NCC, has helped us to investigate a key application area where the use of lignin could have a huge impact on global sustainability.

"Our work has paved the way for further collaborations, and the wider network of the NCC and iCAST will be highly valuable to promote our findings and achieve real-world impact."

Dr Callum Branfoot, MRSC, Research Engineer, Materials Science, National Composites Centre says:

"The outcomes of this project underscore the transformative impact of sustainable materials. The project has highlighted the potential of lignin in composites, however challenges still remain. We eagerly anticipate continued collaborations with Sonichem to turn sustainable composite materials into a reality.

"We encourage companies with an interest in our work to participate and engage in the NCC's research programmes to become part of a sustainable future."

Next steps

The journey is far from over. An innovative UK project is on the horizon, welcoming new partners to further explore and develop lignin's potential. The forthcoming CARMA Project aims to tackle challenges and unlock the full capabilities of lignin in composites.

Businesses of all sizes are invited to actively engage with NCC's upcoming materials and sustainability-focused research programs, contributing to the creation of a sustainable future. This includes prospective customers interested in sustainable bio materials and manufacturing capabilities, with a particular focus on SMEs.

We’d love to hear from you. If you’re interested in getting involved, you can get in touch at: [email protected]