31 July 2023

Introduction

As the transition from fossil fuels to a hydrogen (H2) economy accelerates, so does the need to repurpose the existing network infrastructure to transport H2 from generator to consumer. It’s in this context that using composite pipes can help unblock both economic and technical barriers. To this end, the NCC has invested in developing its capability and knowledge of manufacturing thermoplastic reinforced piping to support the energy industry on its journey to a hydrogen economy.

Challenge

As part of the Hydrogen Innovation Initiative (HII), a collaboration bringing together the strengths and capabilities of the Catapult Network and partner innovation centres, the NCC is working to help industry and customers overcome the technical and economic barriers to innovation in areas that include hydrogen pressure vessels, cryogenic storage tanks, and composite pipes.

Because of its low density, hydrogen needs to be liquified or compressed to high pressures to be stored. This means developing cryogenic tanks, high-pressure storage vessels and a distribution network far beyond the needs and capabilities. This is where composite materials’ low-weight, mass-efficient qualities have a big part to play, not only in storing hydrogen but also in transporting it through a next-generation pipe network to where it will be needed.

Innovation

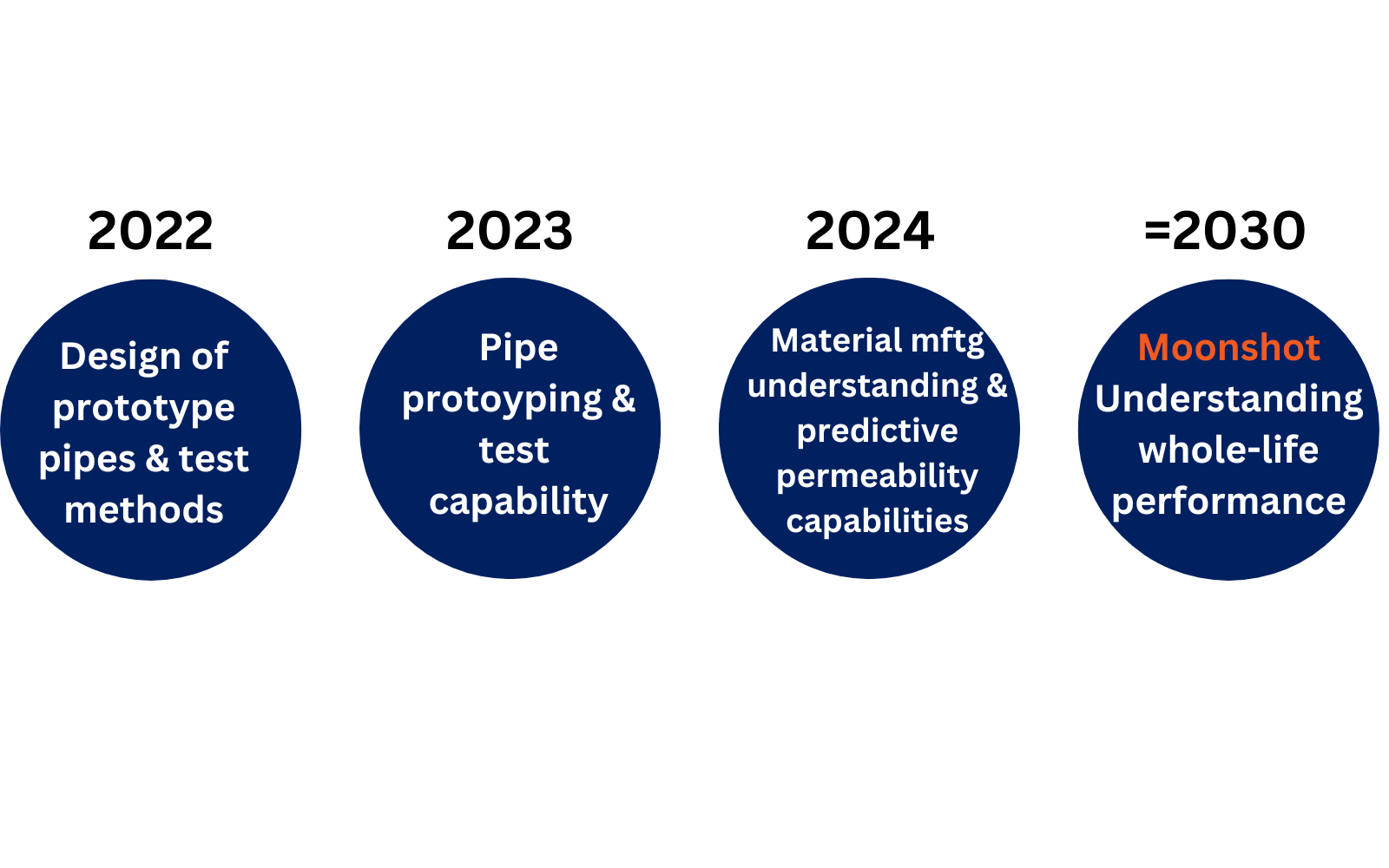

At the NCC, our cross-sector hydrogen team is working to overcome the challenges of deploying composite pipe solutions with a programme of work that will help establish a robust supply chain in the UK. Two years into our journey, we’ve already developed our own manufacturing capability in line with a clear roadmap to 2025 and beyond.

Our on-site facility now offers consulting, as well as a functional and structural design capability, which puts us in a great position to help customers and industry make the most of both the technical and market and opportunities the hydrogen economy will bring.

Impact

In 2023, we’re designing and prototyping pipe concepts to meet the DNV-ST-F119 industry standard for the use of thermoplastic composite pipes in critical offshore applications. And by 2025, we’re aiming to have a comprehensive prototyping and fully qualifiable product design capability based on a regulatory framework currently being developed.

Beyond that, we’ll be looking to reduce the through-life burden of infrastructure by developing ‘smart pipes’ with integrated sensors that provide real-time data monitoring and feedback on flow and pipe performance. It’s this type of pipe that will enable the new and next-generation hydrogen infrastructure we’re going to need to power our homes and industry.

For more information about our programmes of work on thermoplastic composite pipes (TCPs) for hydrogen distribution, email: [email protected]