11 April 2025

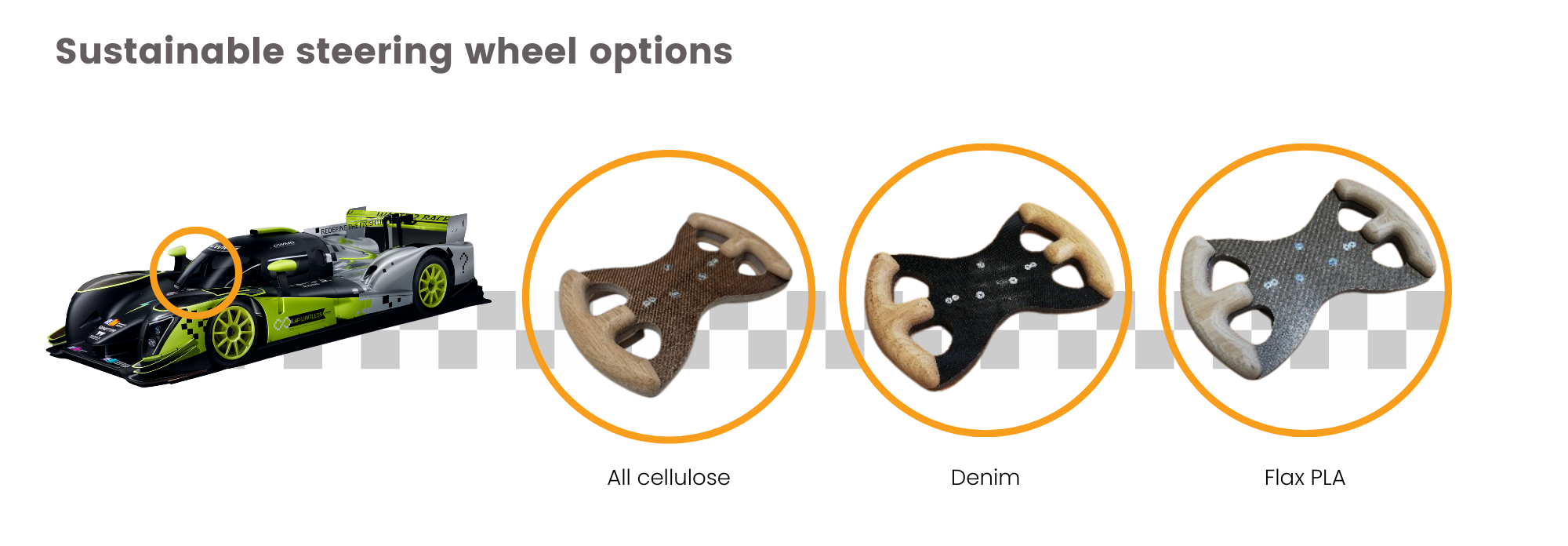

The NCC (National Composites Centre) has developed steering wheels that include one of the most sustainable options of its kind. This effort supports Waste2Race, a project aimed at building a hydrogen-powered car to advance knowledge in hydrogen-powered vehicle technology, led by WMG, University of Warwick in partnership with University of Leeds.

Challenge

The challenge was to manufacture a steering wheel for a Ginetta LMP3 sportscar while minimising environmental impact with reasonable performance, cost, and durability. Sustainability in manufacturing extends beyond using eco-friendly materials—it must include reducing the carbon footprint, minimising waste, and balancing overall environmental impact.

Traditional materials such as carbon fibre and aluminium are widely used in manufacturing due to their performance advantages, but they are resource-intensive and generate significant environmental impact. The NCC sought to identify and test alternative materials that could match performance requirements while offering a more sustainable solution. Using a Life Cycle Assessment (LCA) the project clearly measured and analysed the impact of three novel concepts, providing data for informed decision-making.

Innovation

The NCC developed prototype steering wheels for the Waste2Race project using innovative materials: flax-epoxy prepreg, flax combined with polylactic acid (PLA), waste denim infused with epoxy, and an All-Cellulose Composite (ACC) developed by the University of Leeds. Each prototype also featured oak handles, replacing the original polyurethane foam handles of the Ginetta steering wheel. The three concepts have taken advantage of natural fibres, bio-based resin systems and recycled content:

- All cellulose: Flax fibre which provides both the reinforcement and the matrix

- Denim: Cotton denim resin infusion plate with oak handles

- Flax PLA: Comingled flax and PLA plate with oak handles

Each material combination was tested for environmental impact, and manufacturability.

Results

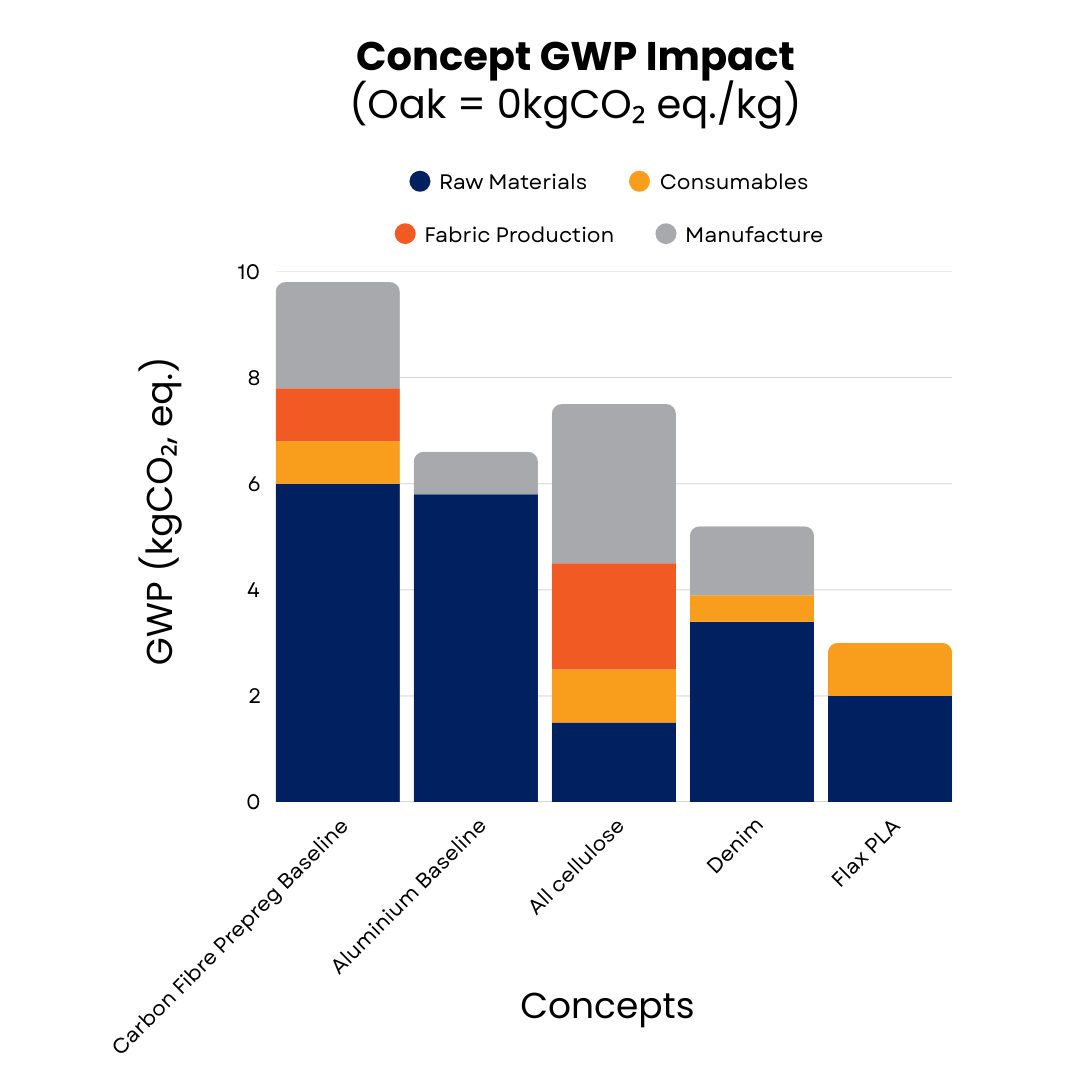

The NCC conducted a cradle-to-gate LCA comparing the PLA and epoxy wheels with traditional carbon fibre and aluminium steering wheels. The results demonstrated a significant environmental benefit:

- All sustainable concepts achieved a 25% - 43% reduction in Global Warming Potential (GWP) compared to the carbon fibre baseline.

- The denim-infused epoxy wheel reduced GWP by 21% compared to the aluminium baseline (assuming oak handles contribute 0 kg CO2 eq./kg).

- Design modifications were implemented to maintain structural stiffness comparable to traditional materials.

- Each steering wheel was successfully manufactured, proving the feasibility of these alternative materials.

The Graph shows GWP impact when the contribution of the oak handles is assumed to be 0.

Impact

This project marks a significant step in integrating sustainability into high-performance manufacturing. By demonstrating the viability of alternative materials, the project highlights the potential for reducing the environmental footprint of composite components.

The successful implementation of LCA practices enables manufacturers to make data-driven decisions about material selection and process optimisation. The project further solidifies NCC's role as a leader in sustainability assessments across various industries. Embracing sustainable materials like flax, PLA, denim, and ACC, could see manufacturers develop a clear pathway to eco-friendly production processes.

James Meredith, Chief Engineer for Sustainable Materials at WMG said: “WMG were delighted to work with NCC on the Waste2Race project. The car will be used to highlight some of the cutting edge research in sustainable materials and the steering wheels which NCC have manufactured are a great example of what is possible in this space.”

Michael Ries, Professor of Soft Matter Physics at the University of Leeds said: “It’s exciting to steer our All-Cellulose Composite invention from concept to reality, navigating the journey from idea to its first impactful use case. These demonstrators are an important and viable way to encourage the industry to consider more sustainable options in manufacturing.”

Next steps

Building on these findings, the NCC will focus on geometry optimisation to enhance strength in high-load areas while reducing mass, progressing toward a fully functional, lightweight steering wheel.

Although the future applications of the Waste2Race project remain uncertain, continued material testing will explore real-world functionality, potentially paving the way for broader adoption in mainstream manufacturing for cross-sector applications.

Matt Scott, Chief Technologist for Strategy at the NCC said: “A growing focus on sustainable, bio-based materials reflects both NCC’s commitment and customers’ priorities. Automotive customers expect environmentally responsible products, and these insights into viable alternatives catering to organisations’ sustainability goals has potential for cross-sector application. As environmental legislation evolves, reducing environmental costs will also make strong financial sense. This is yet another example of how collaboration with university partners and across the High Value Manufacturing Catapult network drives innovation.”

With a dedicated team of sustainability experts, NCC offers a comprehensive range of services that are focused on maximising the sustainability of products, processes and business. Talk to our team to explore NCC's range engineering services.