03 March 2025

A project led by NCC in partnership with the Centre of Expertise in Advanced Materials and Sustainability (CEAMS) has established new digital quality assurance and validation capabilities for recycled carbon fibre.

The collaboration harnessed expertise from a consortium of leading research and technology organisations: NCC, the National Physical Laboratory (NPL), Henry Royce Institute with its hub based at the University of Manchester, and industrial partner Cygnet Texkimp.

The innovations achieved directly address a significant barrier to the adoption of recycled carbon fibre for high value applications.

Challenge

Demand for carbon fibre is set to increase 18% by 2030[1], fuelled by its applications in next-generation aerospace, transportation, energy and hydrogen products. However, there are limited high value end-of-life solutions for carbon fibre waste, while its production has a high environmental impact.

In 2022, NCC and UK engineering SMEs B&M Longworth Ltd and Cygnet Texkimp, successfully recycled reclaimed continuous carbon fibres from composite pressure vessels.

This breakthrough demonstrated the potential of recovering continuous carbon fibre. With superior mechanical properties compared to the short fibres typically recovered, continuous carbon fibre is suitable for high performance applications.

The critical next step, undertaken by CEAMS, was to establish a complete end-to-end capability for quality assurance and performance validation of recycled tows, giving industry confidence in the quality of recycled carbon fibre and enabling its wider adoption.

Innovation

The project harnessed the combined expertise of the CEAMS consortium to deliver several key technological advancements.

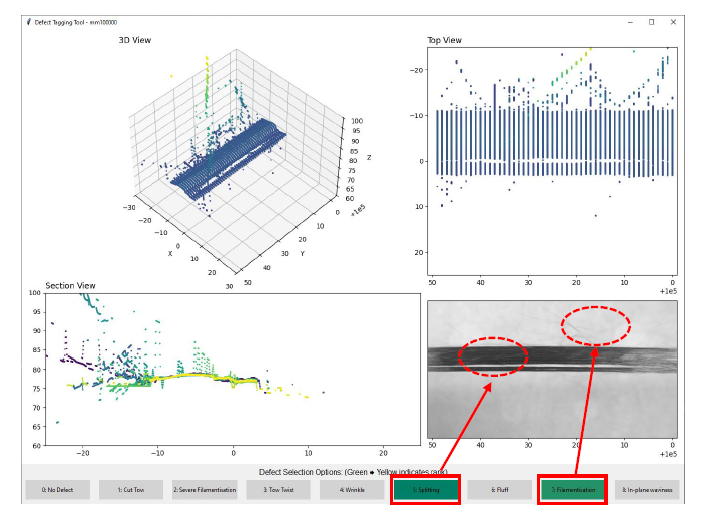

Building on a growing digital and AI capability, NCC developed an AI-powered optical and laser profiler system to scan fibre tow geometry, detect defects, and flag inconsistencies. NPL deployed their world-leading expertise in materials measurement to develop an inline Raman spectroscopy technique to assess the mechanical properties of recycled carbon fibre. This paves the way for integrated, real-time defect detection and tow stiffness evaluation.

Industry partner and fibre processing expert Cygnet Texkimp successfully scaled the DEECOM® fibre recycling process and developed a new test coupon manufacturing system to capture key mechanical properties, such as tensile strength and stiffness.

As the UK’s national institute for advanced materials research and innovation, the Henry Royce Institute worked alongside academic experts at The University of Manchester to develop post-recycling chemical and thermal treatments to clean and refunctionalise the fibre surface - critical to unlocking the full potential of recycled fibre for high-value industries.

Results

The project has driven significant advancements in carbon fibre recycling to decrease barriers to adoption in the UK supply chain. The development of inline inspection technology for recycled carbon fibre also means that bobbin-level material passports can be created for fibre tows. These provide detailed insights into material format and performance characteristics which ensure that recycled carbon fibre can be utilised effectively across high-value industries.

The technologies developed will also drive efficiencies in wider design and manufacturing processes, reducing cost and time, and delivering higher quality products and components.

Impact & Next Steps

The UK’s new National Materials Innovation Strategy, instigated by the Henry Royce Institute, views sustainable advanced materials innovation as a 'fundamental requirement for a resilient economy.’ The above initiative represents a crucial step towards achieving circularity and sustainability for the carbon fibre supply chain, while at the same time supporting the growth of high value carbon fibre production and recycling in the UK.

As a next step, the CEAMS consortium will maximise the impact of these newly developed technologies by working with all parts of the supply chain to demonstrate uses of recovered carbon fibre and address technology and supply chain gaps.

Delegates at JEC World 2025 can find out more by visiting the NCC team at Hall 6, Stand T62. Find out more about NCC at JEC World 2025 here.

NCC services used

[1] Dr Yagoubi, M. 2025. Outlook: Carbon Fiber Global Supply and Demand [Webinar], Composites World, 11 February 2025.