Engineering survival: how advanced materials are reshaping UK defence

By Sean Cooper, Senior Chief Engineer for Defence, NCC

In defence, survivability isn't just another technical specification. The term ‘survivability’ relates to the probability of survival, in essence, what are the chances that someone – or something – will complete their mission and return safely? And when used as a fundamental concept in defence engineering, a focus on survivability develops a culture of protecting those who protect us.

What does this mean in practice? It's all about how well the engineered structures founded on the survivability concept can protect our equipment and our soldiers, sailors and aircrew in combat, and ensure mission success, not least considering the multitude of kinetic, or energetic effects they may experience. And as battlefield threats grow more sophisticated, developing better protective materials isn't just about innovation but about saving lives.

As a nation, our ability to protect our Armed Forces depends not just on technology, but on fostering a robust, innovative UK defence supply chain. This means developing sovereign capabilities in areas like advanced materials and manufacturing, in order to strengthen our security and our industrial base.

Understanding the survivability challenge

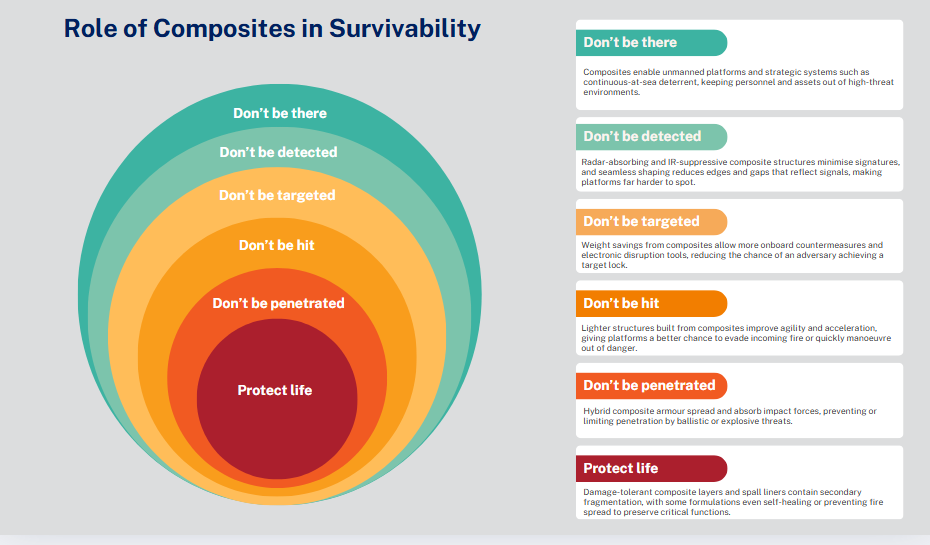

It helps to visualise the concept of survivability in layers, much like an onion, with each layer representing a different line of protection – from the outer onion layer of ‘don't be there’, relating to policy, strategic decision making and deterrence, to the core principle at the onion centre of ‘protect life’ relating to the ultimate aim of returning home. While this metaphoric protective onion seems straightforward in principle, modern warfare demands ever-more ingenious survivability solutions at every layer, particularly as new threat vectors emerge.

Why advanced materials matter

Composites have changed the game when it comes to survivability, particularly in the more central layers of protection such as ‘don’t be detected, ‘don't be hit’ and ‘don't be penetrated’. Their unique properties – especially their high strength-to-weight ratio and ability to absorb and dissipate phenomenal fluxes of energy – enhance protection, while also providing mobility and agility. Which is precisely what modern military operations demand.

For example, we're exploring how new materials applied in layered structures or interwoven into complex forms can better absorb and dissipate the energy from ballistic impacts, protecting both people and critical systems. By engineering these materials at the microscopic, or even molecular level at times, we're building protective systems that are lighter than traditional options, but also more effective at countering multiple threats. What’s more, each advance we make supports innovation across the supply chain, creating further opportunities for our industry to grow and compete globally.

The endless cycle of threat and counter-threat

The ongoing evolution of military threats, fuelled by global conflicts and technological advances, requires continuous improvement in protective materials. Take directed energy weapons, including new uses of high-powered microwaves and high energy lasers, for example.

These new types of weapons can exploit material weaknesses, potentially causing catastrophic failure through intense localised heating or electromagnetic interference. Mitigating such effects is an incredible challenge, so to stay ahead of these emerging threats, we’re pushing the boundaries of what's possible, both in materials science for next-generation armour, and advanced manufacturing for new military structural components.

As Tom Newbery CPhys, Land Survivability Scientist, Platform Systems Division at the MoD's Defence Science and Technology Laboratory (DSTL), articulates in a recent publication: "Platform survivability is continuing to be challenged by the pace and scope of threat development. It remains easier to kill a platform than to protect it, with threat development being driven forwards at great pace by on-going conflicts."

Surviving Future Battlefields: The Uk's Approach to Developing Active Protection Systems Interview with Tom Newbery CPHYS Platform Systems Division Dstl, Defence iQ

In fact, it is fundamentally clear that our national security increasingly hinges on how quickly we can develop and deploy advanced material solutions to counter new threats. This is where the NCC has a big part to play – as both a catalyst for innovation and a hub for collaboration between government, industry and academia.

We are challenging the survivability concept and developing new ideas through initiatives like our Composites Technology Forum for UK Defence where we're bringing together the Ministry of Defence, small and medium sized enterprises, academia, and prime contractors to share knowledge, exchange best practice and foster collaboration to address the challenges that no one organisation can tackle alone. And, just as importantly, to respond as a UK collective, unified and unwavering in the face of changing threats, together on a journey to a new order of rapidly, developed and deployed technologies.

Looking ahead

Every advance we make in defence composites technology enhances the protection for our Armed Forces. It also creates opportunities for UK businesses to grow, innovate, and compete globally. By supporting our supply chain partners to develop cutting-edge capabilities, the NCC is helping create high-value jobs, drive exports, and strengthen the economic foundations of our national security.

As we push the boundaries of materials science, we remain fully committed to two interconnected goals. One: ensuring those defending our nation have the best possible protection. Two: catalysing the growth of a world-leading UK defence industry.

This twin focus on innovation and industrial development is as much about technology as it is about building sovereign capabilities that make our nation safer and more prosperous. With continued investment in advanced materials R&D and strong partnerships across the defence industry, the UK will stay at the cutting-edge of defence technology, building a dynamic, innovative supply chain that creates value at home and abroad. But, to maintain this momentum, we must act to bring together expertise, accelerating innovation and ensuring the rapid deployment of new solutions. The future of survivability depends on our ability to collaborate, adapt, and lead. Now is the time to step forward and be part of this mission.

Join us in shaping the future for defence survivability. To learn more about the NCC’s Composites Technology Forum for UK Defence, email us today on the following address: [email protected]

The future of survivability starts now.