Enabling innovations in wing aerodynamics towards net zero aviation

Engineers at NCC, part of the High Value Manufacturing Catapult, have successfully delivered the design and manufacture of vital one-off flying parts to facilitate UK’s capability towards accelerating new technologies to decarbonise the aviation industry. The wing demonstrators are in support of Airbus’ innovative eXtra Performance Wing project to optimise wing aerodynamics and aircraft performance through hinged wingtips inspired by the biomimicry of seabirds.

The project

Airbus’ eXtra Performance Wing will integrate breakthrough active control technologies that can adapt the wing shape to suit flight conditions, improving aircraft performance and reducing emissions. The technologies could be utilised on a variety of product scenarios.

The Challenge & Enabling Innovation

Severe turbulence in flight creates high aerodynamic loads which become the key sizing criteria for the wing structure. As we move towards more efficient high aspect ratio wings, these loads become even higher and may result in an unfeasible wing design.

To address this challenge, the eXtra Performance Wing will use a Cessna Citation VII to flight test new systems including hinged wingtips and an adaptable trailing edge which can be used to modify the wing shape mimicking a bird’s ability to adapt to flight conditions. This could reduce the maximum loads on the wing, enabling the use of higher aspect ratios and unlocking their potential fuel burn benefits.

NCC’s support was sought to design and manufacture the key structural elements for a 6-metre section of the wing to relevant aerospace standards.

Enhancing aerodynamics requires the eXtra performance wing to be longer, thinner, and lighter than the standard wing – causing it to be more flexible, and more susceptible to turbulence. With part funding from the Aerospace Technology Institute (ATI), the structural design phase of the demonstrator wing part was led by Airbus in a close partnership with specialists from Expleo, the University of Bristol, and NCC. NCC have led the composite manufacturing phase, the scope of which included the design and fabrication of unique tooling suitable for the manufacture of the one-off flying parts.

Results & Next steps

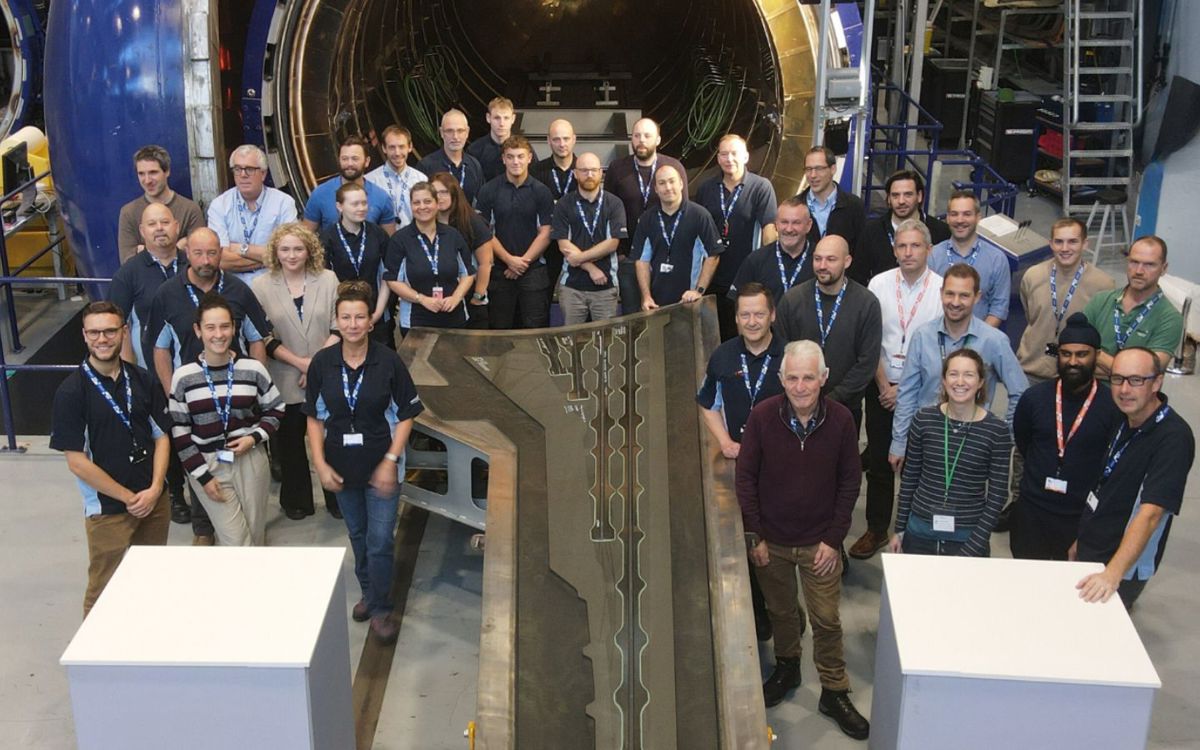

Over the course of 18-months, a dedicated in-house team of more than 50 NCC engineering specialists across aerospace design, stress testing, tooling, composites moulding, and manufacture worked to successfully deliver 28 primary structure composite parts - stringers, spars, and wing skins - to Airbus's Wing Technology Development Centre on Airbus Filton site.

The parts will be assembled into the eXtra performance wing, complete with hinged wingtips, before being installed onto the demonstrator aircraft. The flight testing phase is expected to take place in Cazaux, military airspace South West of France.

Impact

In an NCC first, the team has demonstrated the centre’s capability to not only deliver high value flying demonstrator components, but also do so for one-off components. The added rigour, knowledge and experience gained through the project helps to build and maintain the UK's position as a global centre of excellence and innovation, whilst also helping to support and develop the supply chain for aircraft wing manufacture.

Sarabpal Bhatia, eXtra Performance Wing Demonstrator - Wing Delivery Team Leader for Airbus Operations Ltd said:

"The Airbus and NCC teams have collaborated on the design and industrialisation of primary structure composite components for the eXtra performance WING demonstrator wings. These manufactured high aspect ratio wing components have been integrated into the wing assembly in Filton, which are targeted to be installed on the flying demonstrator aircraft next year in France."

Kevin Mee, Head of Aerospace at NCC said:

"The valuable expertise developed on this project will continue to help NCC lead advancements in industrial design and the adoption of cutting-edge manufacturing technologies – particularly in the pursuit of delivering transformational innovation to advance net zero flight. This also expands our manufacturing testbed’s end-to-end engineering services for aerospace customers keen to trial next-generation process innovations."